Meat Supply Chain Optimisation

Meat supply chain optimisation is essential because the industry balances a variable biological product (the carcass) against fixed market demand (the cut list), operating on razor-thin margins.

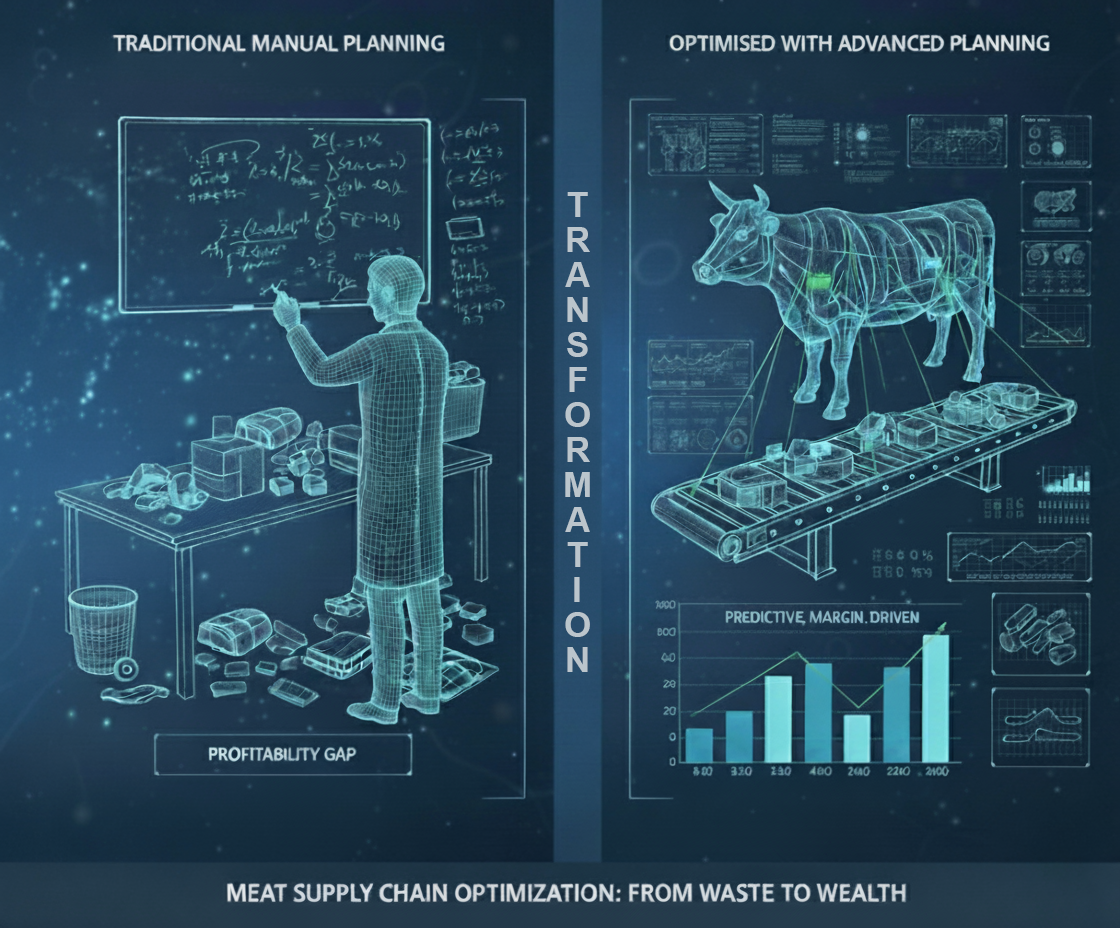

Inefficient, manual planning leads to a profitability gap. High-value cuts are often misallocated to low-margin products, causing sub-optimal yields and significant stock waste.

Implementing Advanced Planning Systems (APS), allows businesses to mathematically calculate the most profitable cut-plan for every animal. This transforms the operation from a reactive process struggling with logistics and waste into a predictive, margin-driven supply chain, delivering multi-million pound profitability turnarounds

Carcass Balancing Optimisation: The Key to Meat Processing Profitability

The Core Conflict in the Meat Supply Chain: A Margin Killer

In high-volume meat and protein processing, profitability hinges on converting variable, biological supply (the carcass) into fixed, specific retail and

The reality is that no two carcasses are identical, yet your production plan must consistently fulfill orders for specific cuts and volumes while maintaining strict quality and shelf-life standards.

Without an advanced planning solution, this leads to critical operational issues that erode profitability:

- Sub-Optimal Yields: Manual planning fails to calculate the most profitable cut-plan for every carcass, resulting in tons of high-value cuts being used for low-margin products.

- Excess Waste: Poor balancing and inventory control lead to costly stock-ageing and spoilage (shelf-life expiration).

- Disconnected Planning: Silos exist between livestock procurement, deboning, and customer relationship management fulfilment, leading to constant firefighting and high logistics costs.

Why Spreadsheets and Legacy ERP Systems Fail

Traditional planning tools and legacy

The Three Pillars of End-to-End Optimisation

BD Solution specialises in Process Re-engineering and

Predictive Supply: Livestock Forecasting Integration

Optimisation must start at the source. We move planning beyond just sales history by integrating livestock forecasting into the S&OP cycle.

This ensures procurement decisions are guided by future retail demand, accurately predicting the quantity, quality, and specific yields of incoming supply weeks in advance. This predictive capability massively increases the accuracy of your upstream planning, eliminating costly surprises.

Maximising Cutout Yield: The Carcass Balancing Engine

This is the nerve centre of profitability. We implement the t optimisation engines to mathematically calculate the most profitable “cut list” for every single carcass or primal.

Drawing on our experience, including leading the end-to-end optimisation across circa 20 abattoir deboning plans for Australia’s largest supermarket, we configure the system to:

- Dynamic Cut Planning: Automatically determine the best allocation of primal cuts to specific end-products based on real-time margin targets and demand signals.

- Production Sequencing: Optimise the flow on the deboning floor to minimise setup times and match daily kill volumes to the most profitable combination of retail cuts.

Case Ready Meat (CRM)CRM production plan

Synchronised Logistics and Inventory Control

Optimised production is useless if inventory control is weak. The

- Waste Reduction: Accurate shelf-life management reduces stock waste from spoilage.

- Service Level Control: We use scenario planning to model and manage inventory buffers, ensuring high customer service levels without excessive capital tied up in stock.

- Logistics Optimisation: The production plan is directly linked to the distribution network, minimising transport costs and delivery time windows.

From Volume to Value: Measurable Financial Outcomes

The results of migrating from manual planning to an optimised

The Competitive Edge

Ready to Transform Your Meat/Protein Supply Chain?

If your business is struggling to balance variability with profitability, relying on legacy systems, or simply seeking to extract maximum value from every carcass, it’s time to talk to an expert.

Stop managing complexity—start mastering it.